2027/03/27

2027/03/27

| MOQ(piece) | Price(CNY) |

|---|---|

| 1 | 0.1 |

product description:

This machine installs the offset printing coating base paper on the smooth metal circle plate of the cross-marking machine, then inserts the pencil into the pen holder and tightens it, adjusts the clamping position, keeps the lever in balance, and makes the lead core contact the coating The original paper is drawn in parallel. Scribe 15 lines at a time, and the length of each line is 60mm. After 15 lines are drawn each time, continue to scribble by rotating 45 degrees for a total of 4 times. Take a 26mm square at the center of the scribe line as the test sample paper.

Meet the standard: QB/T 2774-2006 clause 5.5 and GB/T 26704-2011 "Pencil" pencil concentration test requirements

Design:

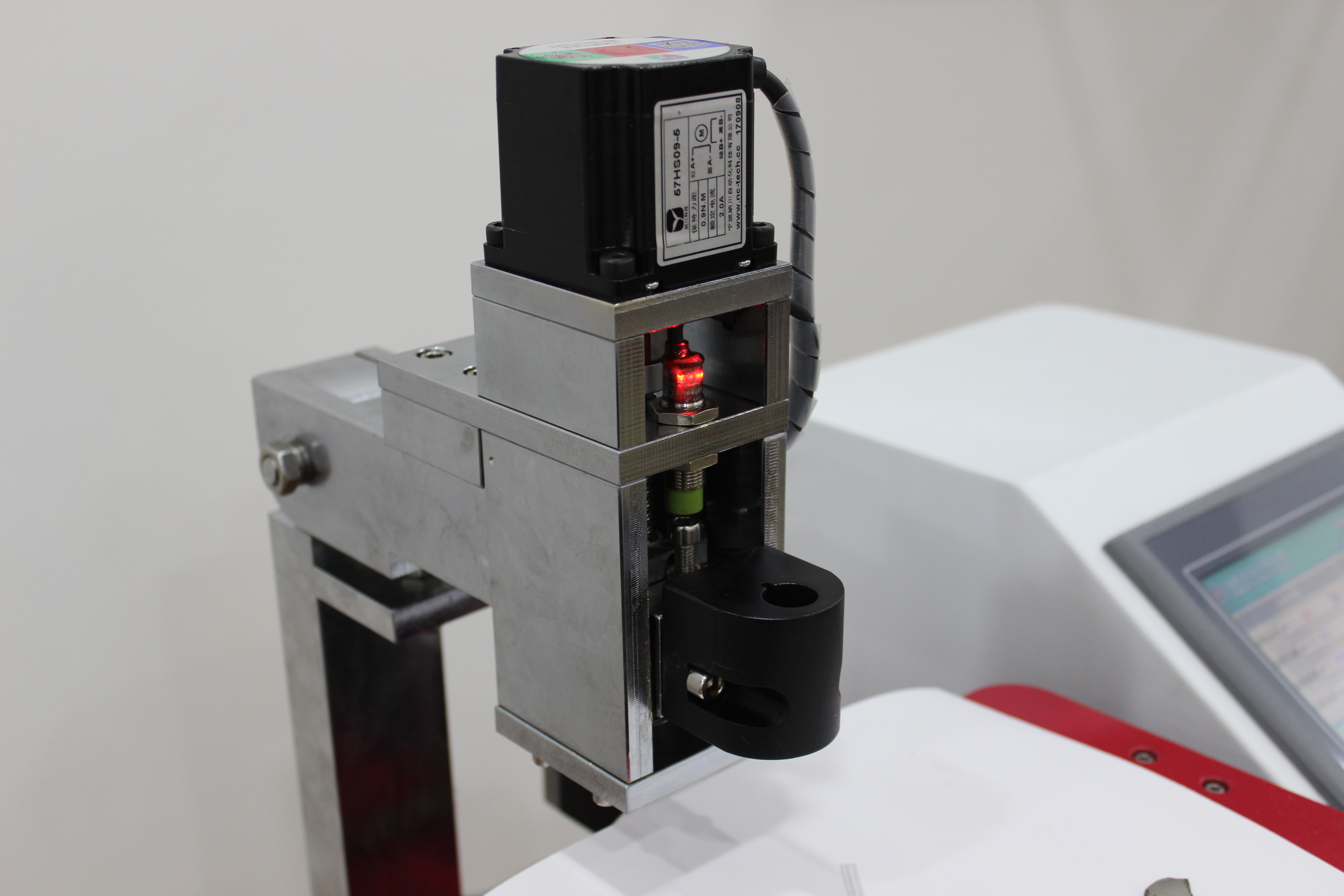

1. The horizontal, vertical and angular rotation are all driven by 3 servo micro-step motors, driven by servo micro-step drivers, Delta 24 point PLC programming control, 7-inch touch screen display operation. Scribing speed, spacing, and corner can all be set digitally to achieve precise control.

2. Fixture: A lever weight balance design is used to superimpose weights in the state of adjusting the level and balance to ensure the accuracy of the marking gravity; the fixture can be adjusted up and down.

Technical Parameters:

1. Cable length: 60 mm;

2. Two 300 g and 500 g weights;

3. Rotation angle: 45°;

4. Counter: 7-inch color touch screen display; Shenzhen Samkoon EA-070B

5. Microcomputer control, automatic angle rotation and line drawing, precision digital adjustment of the angle, automatic compensation;

6. Running speed: 0-110 characters/min adjustable;

7. The lead clamp can be adjusted up and down, and the weight balance can be adjusted;

8. Accessories: ① 1 pack of W14 metallographic sandpaper;

②2 core-point gauge plates (1 each with a diameter of 0.6mm and 0.7mm);

③210g/m2 offset printing coated base paper 1 pack.